Introducing Livium

Our greater purpose

At Livium, we lead the circular economy in electrification – creating solutions for the lithium-ion circular battery materials industry. We are proudly Australian, with values of environmental stewardship and social responsibility. Our cutting-edge technology, indisputable science, and inventive solutions deliver for all.

We are inspired by our people’s passion to deliver a zero-carbon environment. And empower them with a workplace where respect and safety thrive. We are highly agile and responsive to clients, colleagues, our partners, and shareholders.

What we provide

Our values: SPARCS

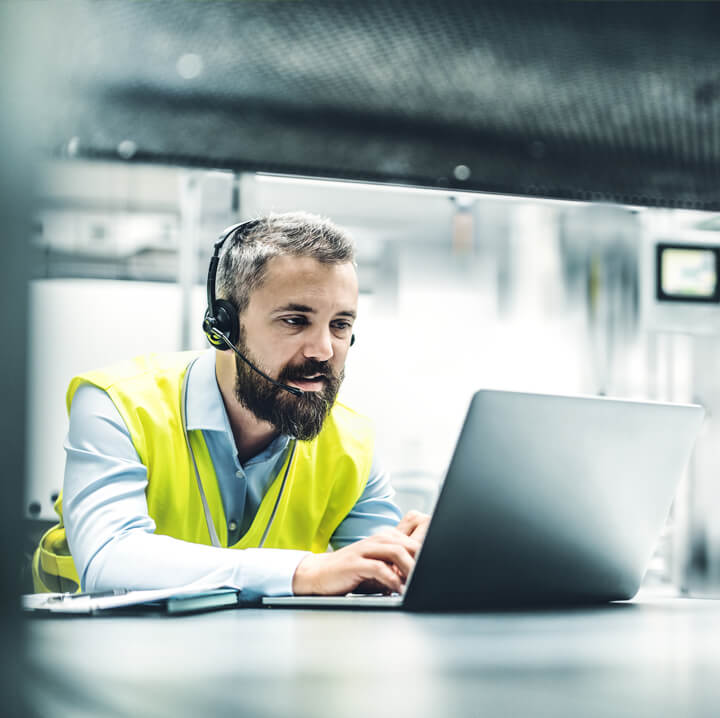

Safety

We chose safety first every time, we don’t start unless it’s safe and we stop if it becomes unsafe.

People

We take a people centred approach. We are passionate about the difference we make. We are trusted by our partners and build meaningful, long standing relationships.

Active

We act in a purposeful way that involves positive action. We are clear on our role and what success looks like. We have a can-do attitude and strive to go the ‘extra mile’.

Respect

We respect and trust each other, and all have a voice. We listen intently to build mutual understanding. We solicit and act on feedback.

Creative

We use technology to develop innovative solutions to accelerate global electrification. We are first movers and ahead of the ‘game’.

Sustainable

We each play a role in making the world a better place. We are working towards a net zero-carbon environment by supporting global electrification.

Past, present, future

Joint Development Agreement

Joint development agreement entered into with Mineral Resources Limited (MinRes) related to LieNA® technology. VSPC product independently tested by Novonix.

Envirostream Acquisition

Acquisition of Envirostream, an operating recycling business. PFS completed for 10,000tpa LFP Facility.

VSPC Acquisition

Acquisition of VSPC, a developer of cathode active materials to enhance the battery technology portfolio.

Mining Exploration

Incorporated as an Exploration Company with activities across initially iron ore, copper and gold – Company name was Midwinter Resources NL and subsequently Cobra Montana NL.

Circular economy

Where we play

We seek to lead and enable the global transition to sustainable electrification, delivering a better world. We do this by providing critical materials for the circular battery industry through battery recycling, lithium chemicals and battery materials.

LIT covers every touchpoint of the lithium value chain through its operations and strategic agreements.

Exploration and Mining

Investments in lithium exploration assets

Lithium Chemicals

Patented lithium

extraction technology

- Current commercial lithium extraction yields are -50-70%1

- LIT’s technology can process fine and low-grade materials to improve mining yields by up to 50%1

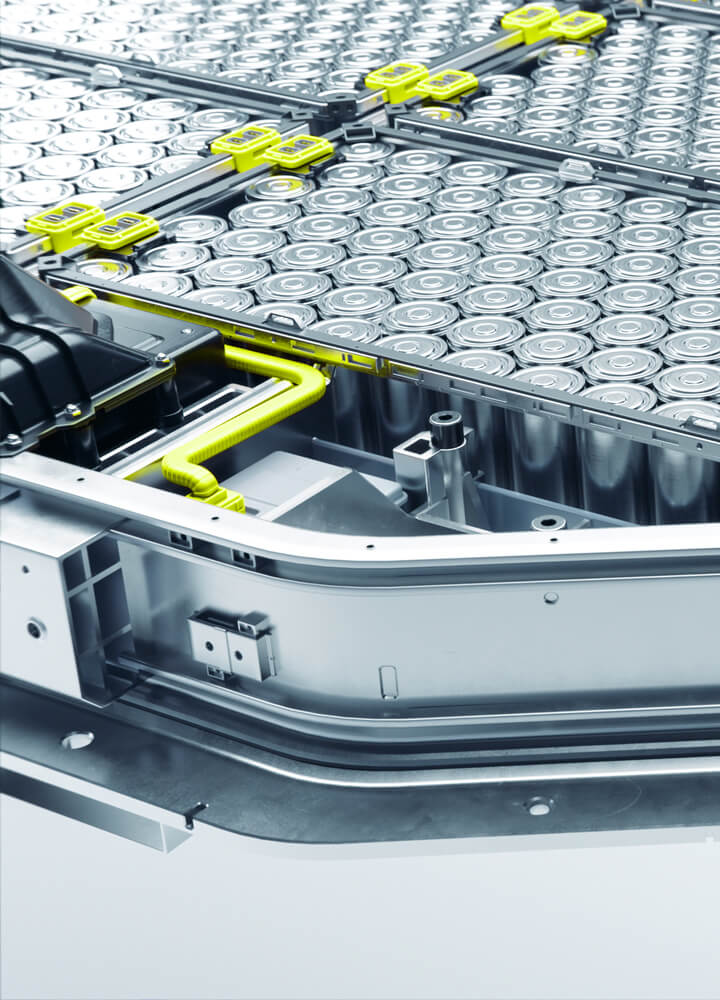

Battery Materials

Patented battery materials production process

- 95%+ of the world’s lithium ferro phosphate (LFP) is manufactured in China2

- LIT have verified it’s LFP product, manufactured using a commercially competitive process

Battery Manufacturing

Strong partnerships with leading battery cell manufacturers

Battery Recycling

Revenue generating battery recycling operation

- Lithium-ion battery waste is expected to grow at 20% per year through to 20363,4

- LIT is Australia’s leading lithium-ion battery recyclers with on-shore processing capabilities

Corporate

To reach Net Zero 2050, battery innovation is required. Supporting battery technology innovation is critical to tackling Australian policy objectives, by lowering costs, increasing safety, enabling availability and uptake, and to meet demand.